Kategorier

- Vår blogg (61)

- Teknisk support (15)

Med den snabba utvecklingen av industriell produktion, Strömförsörjningssystemet spelar en allt viktigare roll i industriell produktion, Så det här systemets brandsäkerhetsförebyggande blir mer och mer framträdande.

>Hela strömförsörjningssystemet består av kablar för att ansluta delarna som helhet, Så när en brand bryter ut i en del av systemet, Elden kan snabbt spridas till andra platser längs överföringskablar och äntligen orsaka enorma ekonomiska förluster.

Dessutom, De flesta isoleringsmaterial i elkabeln är organiska polymermaterial, När förbränning kan producera en stor mängd giftig rök, Äventyrar människors liv på platsen.

Så det är särskilt viktigt att göra ett bra jobb inom brandsäkerheten i det industriella kraftförsörjningssystemet, vid brand, Vi kan snabbt och effektivt släcka elden, Det är av stor betydelse för skyddet av personlig och fastighetssäkerhet, Aerosolsläckningssystem är produkter som snabbt och effektivt kan släcka klass B -bränder och elektriska bränder.

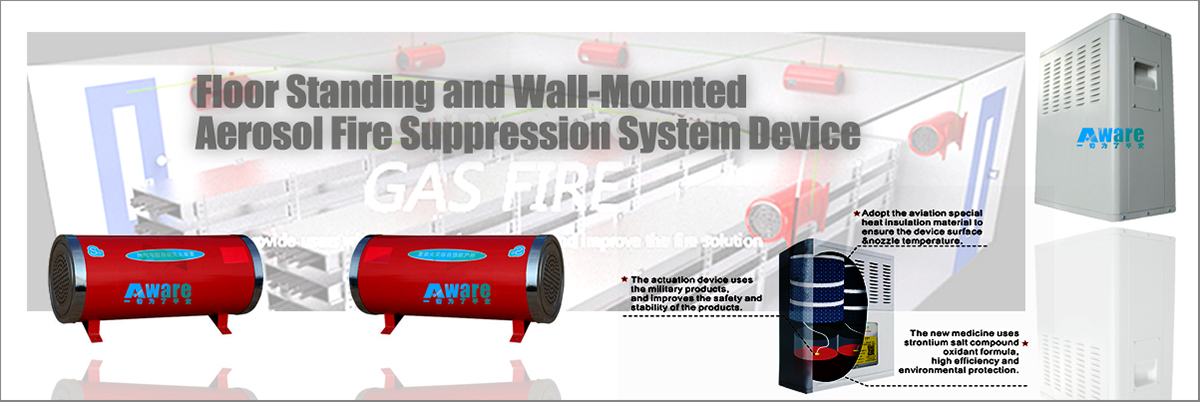

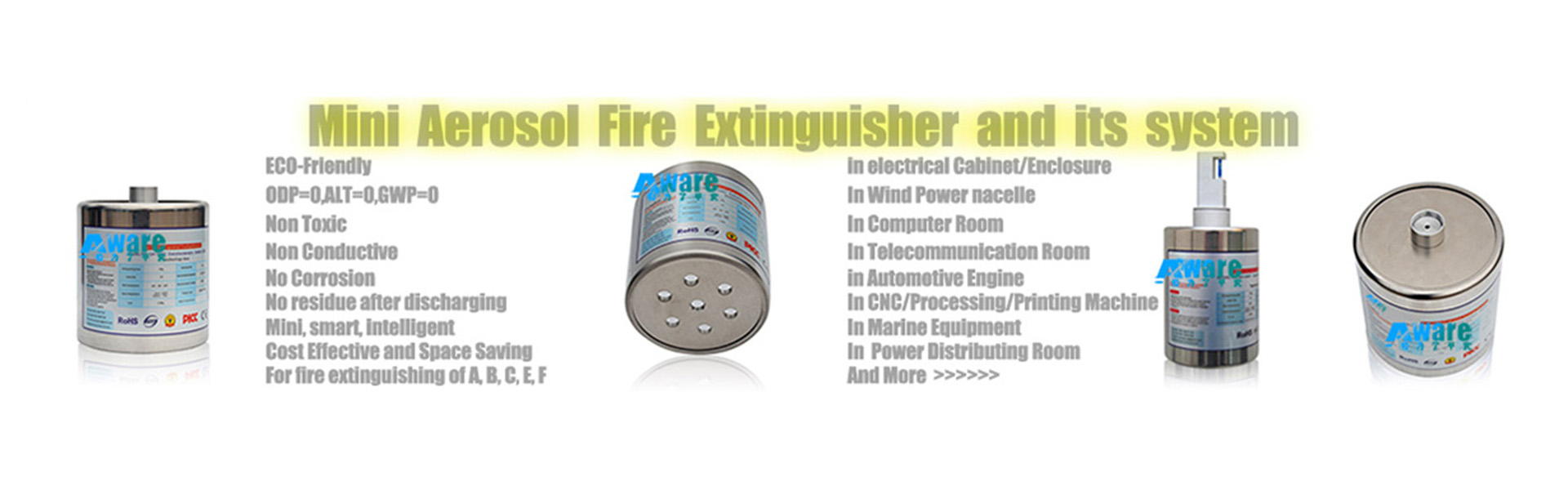

Aerosolsläckare är en typ av produkt som skiljer sig från andra typer av gasbrandsläckande enheter, det har många funktioner som många andra produkter inte har: lätt att använda och installera, kräver inte att ett komplext rörledningsnätverkssystem fungerar, kostnadseffektivt, lång livslängd, Enkelt att transportera, icke-toxicitet, icke-korrosion, Lätt och kompakt, mycket effektivitet i brandundertryckning, viktigast, det kan utformas enligt faktiska rymddimensioner, Så mycket lämplig för användning på olika komplexa platser för industriellt kraftförsörjningssystem.

Så vad är brandkarakteristiken hos industriellt kraftförsörjningssystem, Vi avslutar med följande tre viktiga punkter:

Kabeltunnlar, kabelgravar, kabelinterskikt, och kabelaxlar är alla platser där kablar läggs, dock, Kabelns isoleringsskikt kan förstöras eller isoleringsstyrkan kan minskas under kabelens läggning eller långvarig användning, vilket resulterar i en kortslutning, En elektrisk båge skapas som orsakar förbränning; Och när du lägger oljefyllda kablar, Öka droppen inte följande krav, orsaka fenomenet med oljeläckage, Det finns också en risk för eld; Andra faktorer kommer också att orsaka elden: användning av långvarig överbelastning, Dålig gemensam kontakt, Den yttre elden hoppade in och så vidare.

Den inre miljön i kabelnivåer, kabelinterlayer, och kabelaxlar är i allmänhet smal, låg, lång i längd, och hög i höjd, med täta inre ställningar, färre export, och en komplex miljö. Sådana webbplatser gör det svårt för många rörledningsbrandssläckningssystem att fungera, Men aerosolbrandsläckningsanordningar är särskilt lämpliga för denna komplexa plats. Ta China Baowu Steel Group Corporation Limited som ett exempel, dess kabelunnlar av 2 kraftförsörjningsanläggningar, kabeltunnlar av 3 ståltillverkningsanläggningar, 4 Kabelgravar av kalla rullande fabriker har alla använts väggmonterade aerosolbrandsläckningsanordningar och minisolerosolgeneratorer, med en total mängd 202 uppsättningar, Dessa kabelgravar med längd över flera hundratals meter och höjd över 2 meter, bredd över 2 meter, Kabeln läggs på sidoväggen.

Enligt platsförhållandena, Brandsläckningssystemet är installerat på toppen av kabelgraven, i kabelinterskikt, Vi installerade också 20 uppsättningar av minisolerosolanordningar.

Alla ovanstående projekt har godkänt acceptansen av brandövervakningsavdelningen, fungerar normalt.

Kontrollrum, kraftdistributionsrum, Elektromagnetiska stationer och andra fält är områden där utrustningen är koncentrerad. Den främsta orsaken till bränder i dessa områden orsakas av olika switchar, kablar, etc. Dessutom, Det finns andra brännbara material i rummet som också kan orsaka bränder.

Eftersom elektrisk utrustning i allmänhet inte får använda vattensystem, kan bara använda gasformiga brandundertryckssystem som FM200, IG541, och koldioxid, Särskilt, Aerosolundertryckningssystem tillhör också det gasformiga brandundertryckningssystemet, Så kan också ansöka på dessa platser.

Brand i transformatorrummet beror vanligtvis på några av följande omständigheter:

Alla ovanstående situationer kan göra att de inre brännbara materialen i transformatorn ska sönderdelas av hög temperatur, Och sedan orsaka eld.

Transformatorer kräver i allmänhet god värmeavledning och därför är transformatorrum vanligtvis inte helt förseglade.

Aerosolbrandsläckare, som produkter som kan användas för lokaliserad brandsläckning, är lämpliga för sådana transformatorrum.

Internt komponentfel eller extern brandspridning kommer att orsaka dieselgeneratorbrand. Sådana bränder är typiska kategori B -bränder orsakade av dieselförbränning.

För närvarande, Många industri- och gruvföretag har standby -dieselgeneratorrum, och många generatorrum finns i källaren eller halvkällaren stängt utrymme.

I ett sådant utrymme, En aerosolbrandsläckningsanordning kan undertrycka den typiska klass B -brand.

Kortkretsar och systemfel kan orsaka elektriska skåp och kontrollpaneler för att ta eld.

Elektriska skåp och kontrollpaneler är små och stängda.

För bränder i denna situation, Vi kan använda minisolerosolanordningar mellan 20 och 250 gram.

Aerosolprodukter aktiveras vanligtvis genom användning av elektriskt utlöst släckmedel. Släckningsmedlet tar emot triggerkommandot och börjar släcka elden.

Elektriska triggers är känsliga för elektromagnetisk störning. Det industriella kraftförsörjningssystemet sänder och kör all stark el. Den elektromagnetiska störningen i dessa tillfällen är mycket stark.

Därför, När du installerar aerosolprodukter på dessa platser, Skyddskraven för elektriska starttrådar kommer att vara mycket strikta. Installatörer måste arbeta i strikt i enlighet med relevanta normer, Annars kommer det att orsaka oavsiktliga injektionsolyckor.

Aerosolsystem är säkerhetsvaktarna för industriella kraftförsörjningssystem. särskilt i följande situationer eller fält:

Dess unika fördelar är ojämförliga för andra brandsläckande enheter.

Aerosol Fire Släckningssystem uppfyller fullt ut säkerhetens krav, högeffektiv och miljöskydd. Dess tillämpning i industriellt kraftförsörjningssystem kommer att bli mer och mer lovande.